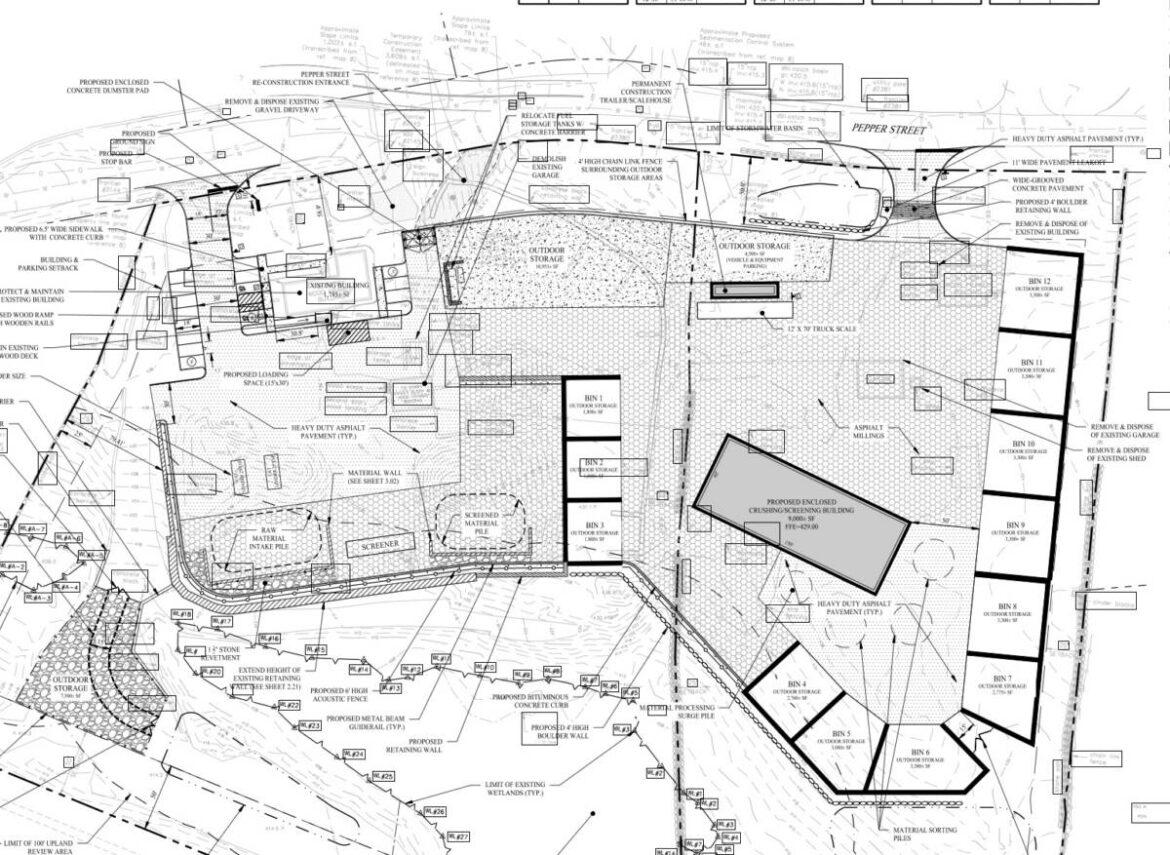

MONROE, CT — Planning and Zoning commissioner approved the construction of Monroe Recycling and Aggregates LLC, a 9,000-square-foot manufacturing facility at 467 and 485 Pepper St., which will produce a product called reclaimed asphalt.

The application by Joe Grasso, owner of The Grasso Companies LLC, was approved with conditions by a vote of 4 to 1, with Leon Ambrosey the sole dissenter.

Voting in favor of the application at the Feb. 16 meeting were Chairman Michael O’Reilly, Vice Chairman Bruno Maini, Secretary Ryan Condon and Robert Westlund.

Town Planner Rick Schultz said the conditions consisted of three major components: a noise monitoring protocol agreement for the duration of the facility, a requirement that all processing of materials be indoors, and 24/7 dust control that is properly maintained.

Debris from floor drains must be picked up, swept and removed.

The operation will entail materials being trucked onto the site and stockpiled before use, so a “well-enforced retaining wall/designated fencing area” must be in place due to heavy equipment pushing this material.

Landscaping is required in front of the property to buffer it.

The commission previously approved an initial plan for a smaller, 4,000-square-foot processing facility at 485 Pepper St., but now the operation has been expanded to two parcels.

Schultz said the existing driveway will be widened and an old house will be converted for offices, while a detached garage is knocked down. The entrance to the other parcel is where the main processing facility will be. An existing house on that property will be removed.

The hours of operation and the amount of equipment used will be the same as in the previous approval.

The developer also agreed to quarterly progress reports to be done by his engineer, ensuring the project is being built in accordance with the approved site plan. If anything deviates from it, Schultz said an application reflecting the changes must go before the commission.

“We just need the protocol measures and staff will deliver the reports to you,” he told the commission.

Ambrosey wanted assurance that a requirement of a manifest for materials brought to the facility is included in the commission’s written approval. Schultz said it was.

“We have to make it mandatory that everything be tested,” Ambrosey said. “I have issues with the asphalt and cement.”

The plan already received an approval from the Inland Wetlands Commission.

All respectful comments with the commenter’s first and last name are welcome.

The so-called manufacturing facility proposed by the Grasso Company LLC to be called Monroe Recycling and Aggregates LLC is being characterized as a manufacturing process in order to get around Monroe’s “no-recycling” ordinance. However, you cannot change the character of a recycling business by merely calling it something else. The business as currently proposed will take reclaimed asphalt to be used as a road base by grinding up old asphalt chunks which is the very definition of recycling not manufacturing.

“Remanufacturing preserves the entire form of a product, whereas recycling involves breaking the product down into its component parts and melting, smelting or reprocessing them into new forms.”

Asphalt Pavement Recycling

“According to the Asphalt Pavement Alliance, reclaimed asphalt pavement (RAP) can be recycled into pavement that is as high, or even higher, in quality as pavements made from all-virgin materials. In addition, the same material can be recycled again and again without losing its value. The asphalt cement, the glue that holds the pavement together, retains its ability to function as glue or cement, so that it is reused for its original purpose. The aggregates (rocks, sand, and gravel) in the original pavement are also conserved. It is estimated that the recycling of asphalt pavement saves American taxpayers more than $2.5 billion per year. It also saves thousands of acre-feet of landfill space each year. Materials from other industries are routinely recycled into asphalt pavements instead of going into landfills. Some of the most common are rubber from used tires, asphalt roofing shingles, and steel and blast furnace slags. Besides being used directly in new asphalt, RAP has been used as road base products, often mixed with concrete.”

Manufacturing vs recycling…If it walks like a duck.